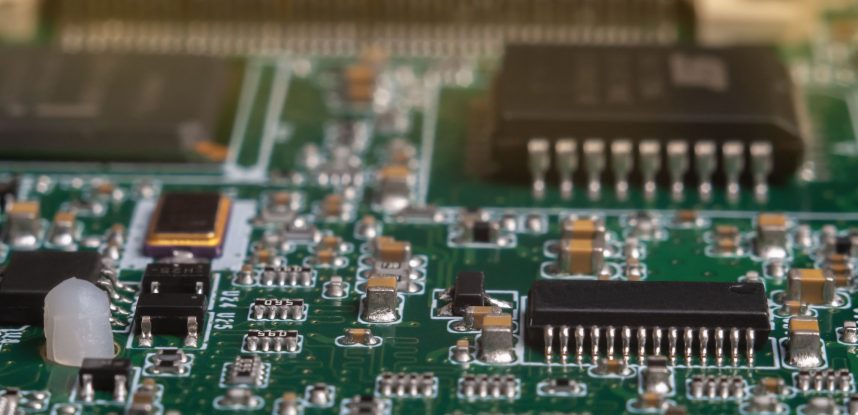

Ask anyone who drives an older car.

As the system ages, it develops its own quirks. You have to jiggle the shifter in park to get the keys out of the ignition. You have to pump the gas twice before it starts up on a cold day. The AC has to be turned off when going up a steep hill on days over 96 degrees. You know that you can get away with just 2/3rds of the thread on the bolts, but only for 6 weeks.

In short, you know that system inside and out: all the bugs, the features, and quirks that impact operation and repair. Unless your mechanic is into vintage cars, though, he’s not going to relish working on an older vehicle. A younger mechanic may tell you the car is “old” and you’re better off just getting a new one, just when the old one was about to become a “classic.”