What is legacy equipment manufacturing?

Legacy equipment manufacturing (LEM) is a new name for an old concept–the production and sale of equipment, machinery, or products that have been in production for an extended period of many years or even decades. Electronics obsolescence has always been an issue, but with the pace of innovation, the increased complexity of equipment, and the essential role that embedded components serve in industrial and defense systems, the challenges that obsolescence brings have become exacerbated.

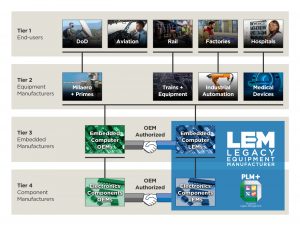

A partnership that benefits OEMs and their customers

Countless organizations depend on large, expensive equipment to complete business-critical tasks, and that equipment often consists of many small components made by equipment OEMs or third-party OEMs. As time goes on, those smaller parts become obsolete, creating problems for both OEMs and their customers. If the customers can’t upgrade, then the OEMs either have to produce a part that doesn’t meet profitability targets, or discontinue the products altogether. And if they discontinue the part, customers will experience hardships such as service interruptions or forced and costly upgrades.

Legacy Equipment Manufacturers (LEMs) solve problems for both OEMs and their end-use customers by producing and servicing parts that are identical to the original. They work throughout the supply chain to support obsolete designs that are form-fit-functionally identical to the originals.

Their partnership with OEMs:

- Achieves supply chain resilience

- Provides critical components beyond obsolescence

- Breaks the costly obsolescence-forced upgrade cycle

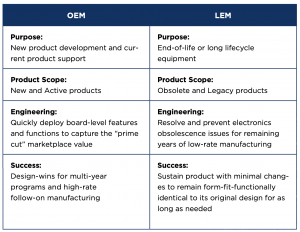

The difference between LEMs and OEMs

While both entities perform similar operations, such as engineering and manufacturing, their purposes and business models are very different.

How an LEM can help you and your customers

LEMs are an essential partner for OEMs, especially in electronics manufacturing, where obsolescence is always a looming problem. LEMs provide the support necessary for end users of legacy products, allowing OEMs to focus on their new and active products and profits, while still maintaining, and often, even improving relationships with their customers. At the same time, they also provide customers and OEMs with more options than simply Last-Time Buys (LTBs) and expensive system upgrades.

Some LEMs, like GDCA, can also assist you in taking a proactive approach towards obsolescence. With the right experience in supply chain management and lifecycle forecasting, we can determine what products are most at risk that are still critical for end-users, and work with you to determine the right solution.