New Source of Supply vs. Second Source of Supply

When a new source of supply isn’t enough

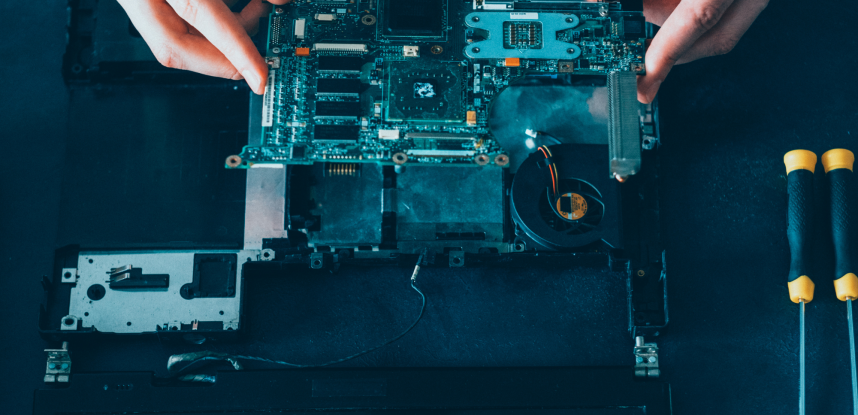

All machines, and the parts that make them up, have a lifespan. Even software compatibility and certifications need to be considered when you have a piece of equipment that you plan to use for a decade or more. With how quickly technology is advancing every year, obsolescence management becomes more vital for any equipment that you plan to use in the long term.

What is a new source of supply?

An important part of obsolescence management is finding a Legacy Equipment Manufacturer (LEM) who can provide a New Source of Supply (NSOS) for parts used in the application or system. A LEM is a manufacturing company that reverses engineers the production capability for a part that’s been re-classified by the OEM as End of Life, but that the customer continues to require support or availability. With the original manufacturer’s authorization (thus avoiding the risk of counterfeits or clones), an NSOS ensures that everything from the manufacturing process of the part is entirely rebuilt to OEM specifications.

While an NSOS is an important tool in the obsolescence management toolbox, it does not represent a viable long-term solution on its own. Securing the ability to support and repair a product will not ensure availability or secure the eventual supply chain issues these older legacy products suffer.

In the long term, an NSOS alone becomes less and less reliable as a solution, especially when you need it for at least a decade. Just because you rebuild the board now doesn’t mean it will still be viable for the rest of the equipment’s life cycle requirements.

Second Source of Supply–an alternative to NSOS

Second Source of Supply (SSOS) is basically a new source of supply, but with the addition of a plan for sustainment to assure availability when you require it, and for as long as you need it. Not only does the SSOS rebuild the board for your equipment, they also ensure that it will be available–and accurate–for as long as you need it. The embedded boards are functionally the same as those created by the OEM, and thus are still workable within the existing structure, no matter how old it might be.

Proactive Solutions with GDCA

At GDCA, we take an innovative approach to obsolescence management, providing our customers with long-term support and sustainment for legacy products that are critical to long-lasting applications. We are OEM authorized and have been trusted for over a quarter of a century with the design, manufacture, and test specifications for thousands of different products. Through our legacy plans, we manufacture new, authentic boards and systems that match your original product, as well as provide contracts for life-cycle assurance, planning, and sustainment engineering. Check out all of the different options available to you, as well as solutions specific to your industry, on our website. If you need a board that is no longer available from the OEM, then visit this link to request a board from us and we’ll discuss with you what we can do to help.