7 Perspectives about Legacy Engineering

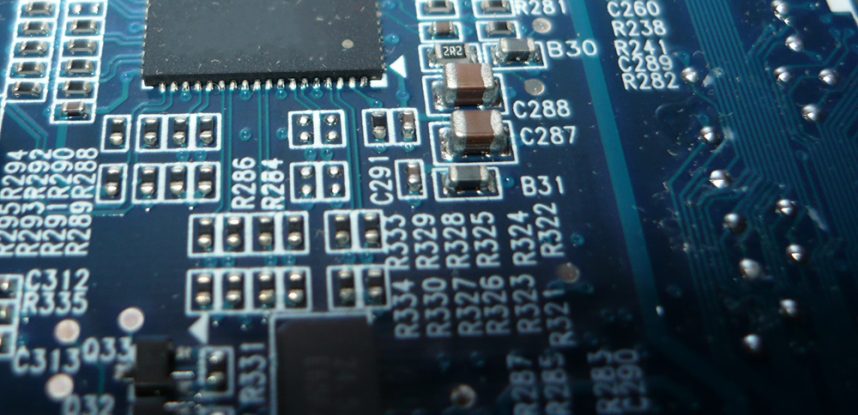

Once component EOL notices have been issued and COTS embedded boards are discontinued, the processes for keeping your embedded systems vital drastically changes and so must your overall thinking about them.

When the supply chain is active, acquiring the boards and components you need requires simply placing an order. Extending or even reviving a product after it’s reached maturity, and affected by discontinued parts, takes many times more effort to support.

Embedded boards older than seven years will typically encounter sustainment issues including EOL’d components, rising production and material costs, and even tribal knowledge drain due to natural staff attrition.

Here are some important things to consider when your system shifts from Active to Mature.

- YOUR ISSUES ARE UNIQUE: It can take up to 80 work hours to assess your needs.

- OEMs AND ENGINEERS LIKE TO BUILD NEW STUFF: It takes a unique culture to sustain products designed by someone else.

- PARTS NEED TO BE SOURCED: Once a component is out of production, finding what you need is more difficult due to counterfeits and supply chain constraints

- TARGETED ENGINEERING may be required to solve obsolescence issues and bring a product back to a state where it can be reliably produced and repaired.

- BOARDS NEED TO BE TESTED: New remanufactured boards go through the same rigorous testing for durability, efficiency and quality assurance.

- TECHNICAL DATA PACKAGES holes require creative engineering efforts to reanimate the capability to support a product.

- PROACTIVE MANAGEMENT is a vital part of predictably maintaining your long lifecycle applications and mitigate unforeseen and costly delays.

When your electronics need to last longer than expected, Legacy Engineering provides reliable and expert sustainment services to deliver form, fit, function compatible embedded products.

It can resolve specific obsolescence issues on a board, and/or recommend alternative approaches to keep mature boards and systems healthy for longer.