True Cost – An Introduction to Lifecycle Optimization

For embedded board OEMs, Lifecycle Optimization and your electronics product portfolio are an important part of profit and loss considerations when determining your business objectives. Aging products’ impact on ROI is regularly overlooked. Component obsolescence, manufacturing bottlenecks and increasing demands on operational resources create gaps that drag down new product introduction and can considerably slow the pace of OEM innovation—undermining efforts to gain competitive advantages in the marketplace.

Learning how to identify and address these gaps is of strategic importance for board OEMs. Lifecycle Optimization is a strategic approach that keeps OEMs in control of products’ profitability, especially after they fall out of the active phase of their lifecycle. This is achieved by tracking and incorporating the true cost of supporting product designs throughout their lifecycle.

The simple truth is that board OEMs are founded on a business model geared toward introducing new products, not on indefinitely sustaining them. At some point in every product’s lifecycle, it begins losing money if they continue support. The first step in optimizing your full ROI is by identifying the operational gaps that allow the true cost of supporting old designs to remain unknown.

Consider This.

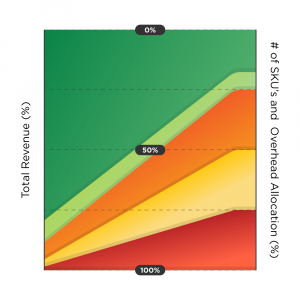

When a product first comes to market, there’s a desired ROI. After a certain amount of time, the ROI for an individual product family is no longer tracked. Due to this lack of visibility, the increased costs of maintaining systems during their active versus mature lifecycle stages go unchecked and unnoticed.

However, in reality, the dollars needed to manage a product in its active phase are not the same as the dollars required for products in their mature/sustainment phases. Playing the game of averages over a product’s lifecycle camouflages the truth until it’s too late.

Product managers (PMs) do the best they can to track cost but as products age, they don’t have access to the correct metrics to do it accurately. They pull from every department to gather the data needed to advise the leadership team on the profits they’re going to deliver. However, without clear guidelines for realizing when a product passes from its active stage to the mature/ sustainment phase, PMs have inaccurate performance objectives and no reference points to guide decisions. As a result, company-wide profitability and ability to meet strategic objectives suffer.

The impact of not having clear insight into the numbers goes beyond profits. Customer relationships built on trust are strained by the EOL/LTB cycle. EOL is a natural eventuality of PLM that can’t be avoided, and OEMs have come to depend on the “LTB Bump” that results from this cycle. However, customers with continuing demand often pressure OEMs to walk back the decision to EOL. The OEMs, out of their commitment to their customers, are often compelled to perform “just one more build.” Yet the decision to support these older designs ignores the reasons why they were EOL’d in the first place. Consequently, the OEM is left dealing with the resulting manufacturing bottlenecks caused by the drain on engineering, manufacturing, and management resources.

What would it mean if you knew the true cost and profitability of every order you take? How could you benefit from that knowledge?