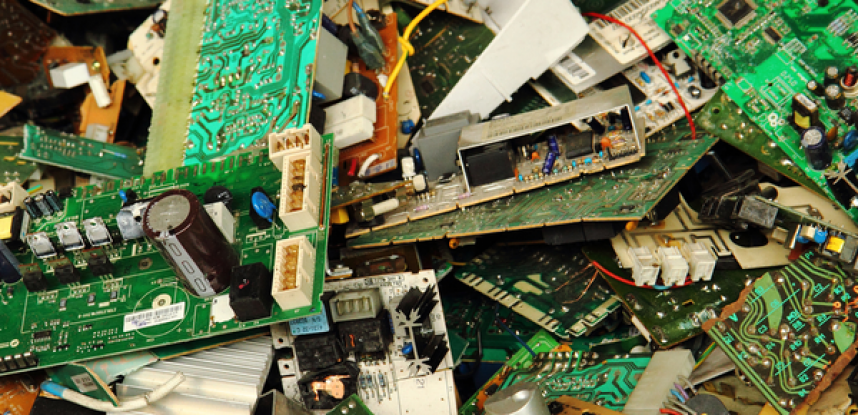

Looking at Legacy: Proactively managing the risk of counterfeit components

In general, defense sustainment and counterfeit avoidance has been left to DMSMS teams and logistics or engineering tactics. However, so far the solution has primarily been to develop standards, authentication and anti-counterfeit technologies. These responses have been critical, but have largely remained reactive and have not produced the dynamic collaboration crucial to maintaining a healthy, proactive supply chain. Instead, each player is left facing inward — focusing on solutions from their own particular positions in the supply chain — but without the resources to truly be proactive.